Integrating foil into your printing project adds a look of luxury and draws your reader’s attention to the right place.

With so many options available, it has never been easier to add the elegant look of foil to your label. Let Premier Printing Solutions help you choose which option would be right for your design.

Cold Foil

Cold Foil is applied to a UV-curable adhesive image on press using a printing plate, creating an image prior to ink application. This inline process allows for an infinite spectrum of color possibilities by overprinting the cold foil image. The Cold Foil process requires little pressure and images lay flat on the substrate. This process would be suitable for large coverage areas. Cold Foil does not respond well to embossing due to surface sensitivity. When embossing is required, hot foil would be a better fit.

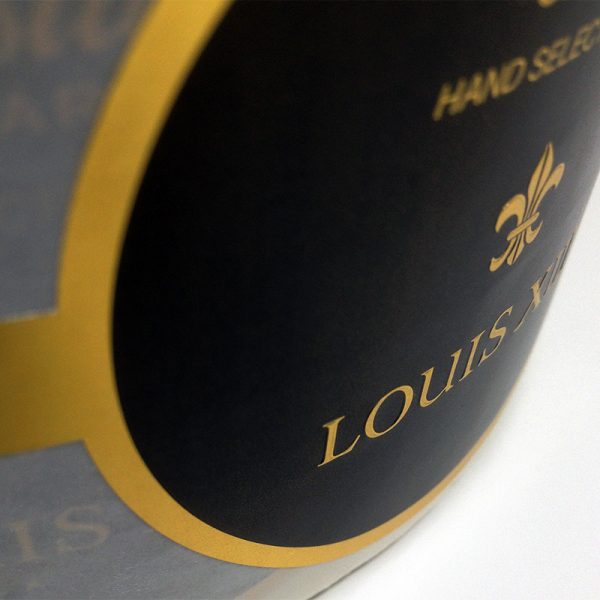

Hot Foil

Hot Foil is stamped onto the substrate using a heated metal die. When the die strikes the heat-sensitive foil, it is pressed into the substrate leaving foil only in the area of impact. This process produces crisp, clean images with the slightest hint of dimension due to the pressure involved. Hot Foil comes in a wide variety of colors and finishes, including gloss, matte and holographic. Hot Stamp can be used alone to create a flat image or used in conjunction with embossing to create a brilliant raised design.